About us

We are fascinated by packaging. Probably because making them is much more complex than traditional printing. Maybe this is why we love it so much. We do not just make boxes. We look at packaging as a much more exciting, creative activity.

From the very beginning, we have been interested in packaging solutions of different colours, shapes and configurations. We had a concrete image in our heads of a gift box made from colourful wrapping paper, which we also realised in the winter of 1992. Then picked up our courage and took our colourful little boxes to the market: more precisely, we chose the Christmas Market in Debrecen. We had a huge success, which sealed our fate once and for all, and we found ourselves in the world of packaging technology.

Our first business premises were a 70-sq industrial kitchen that we rented out.

Two years later, we established our first company, which was the point where the name Sz. Variáns was conceived as a reference to our family names and the varieties of packaging. The founders were the Szakál siblings, Irma and János, who were later joined by Zsuzsa Rácsai, the wife of János. Our first business premises were a 70-sq industrial kitchen, with a few rusty machines, that we rented out. We had to go next door to make a phone call.

We started out with small steps but with big plans, but we soon had to realise that in case we want to survive in this area in the long run, continuous learning and development are indispensable. Creativity was just the beginning, but we also needed a high degree of resourcefulness to address the new needs and problems. It was unavoidable, therefore, to use an increasing number of packaging techniques and production technologies, to keep up with the new trends.

We developed over the years, step by step

We dreamt of making gift boxes using colourful wrapping papers. To our utter joy, we were not the only ones liking these, as we sold thousands of them at the Christmas markets.

All beginnings are hard. We established our first company, Sz. Variáns Limited Partnership. Sz. stood for Szakál (family name), while Variáns referred to varieties in packaging. It soon turned out that our enthusiasm was bigger than our professional knowledge. As business premises, we rented a dilapidated 70-sq-m industrial kitchen, bought a few rusty, out-of-use machines. We had to go next door to make a phone call or send a fax. We used a drawing board to sketch up our designs and visions.

Our success was tapering off, and the production of mounted gift boxes as our main activity no longer covered our expenses. What next?

In Hungary, we were the first to find and started to use open microcorrugated paper for making paper bags, as well as wine and boxes.

In the category of packaging designs and packaging materials, we won our first award in the “Creative Paper” competition.

We became suppliers of IKEA. We made packaging materials from colour, open corrugated paper. Our products became available worldwide. The headcount of our company doubled and reached 18. We had a huge success at our first trade fair.

We added exclusive paper bags to our product portfolio.

We moved to our own business premises on an area of 1200 square meters, and also opened our sales office in Budapest.

From this year on, our designs were realised with a plotter cutting machine, which opened up our possibilities in the field of packaging technology.

In the field of packing materials, we became the primary suppliers of the Herend and the Zsolnay porcelain manufacturies.

We consciously redesigned our company structure. The well-conceived reorganisation of the positions gave a new impetus to production.

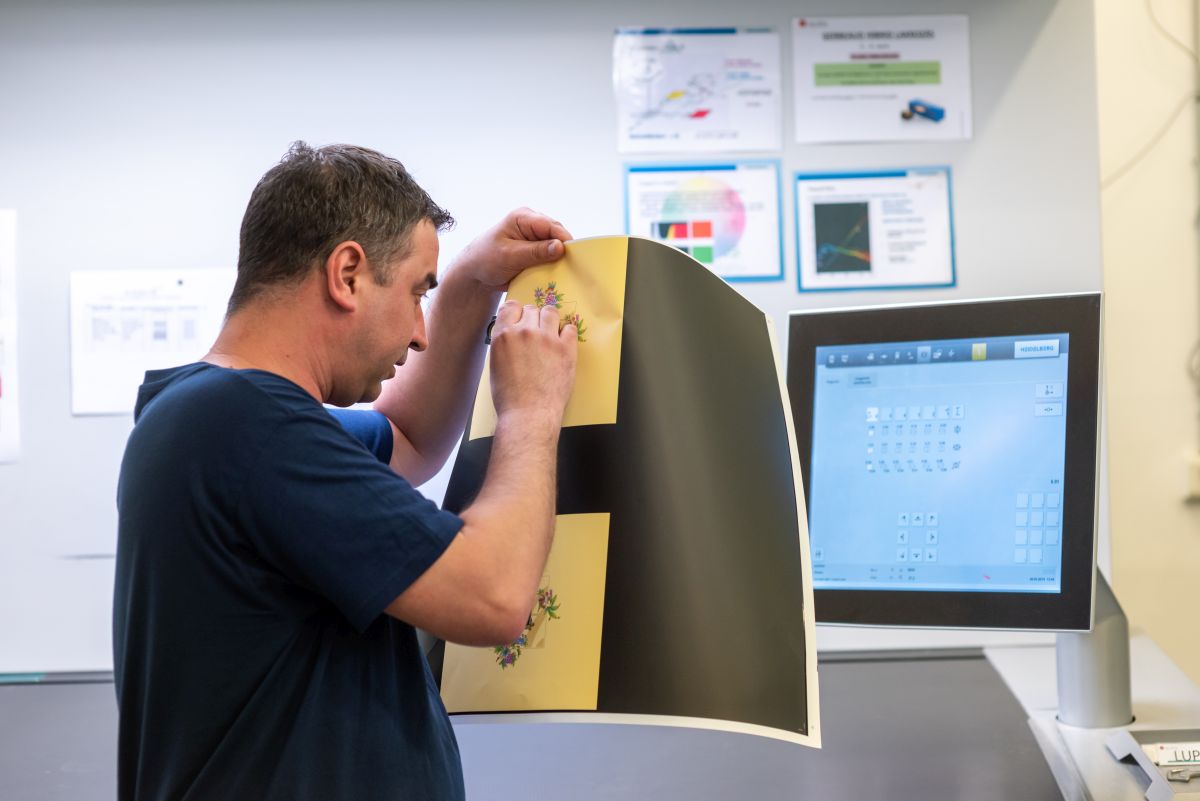

We commissioned our first, 5-colour Heidelberg printing machine.

Our business premises, bought only 4 years before, proved to be too small, and therefore, we moved our printing department to a new location.

As exhibitors, we participated at the advertising gifts fair in Düsseldorf.

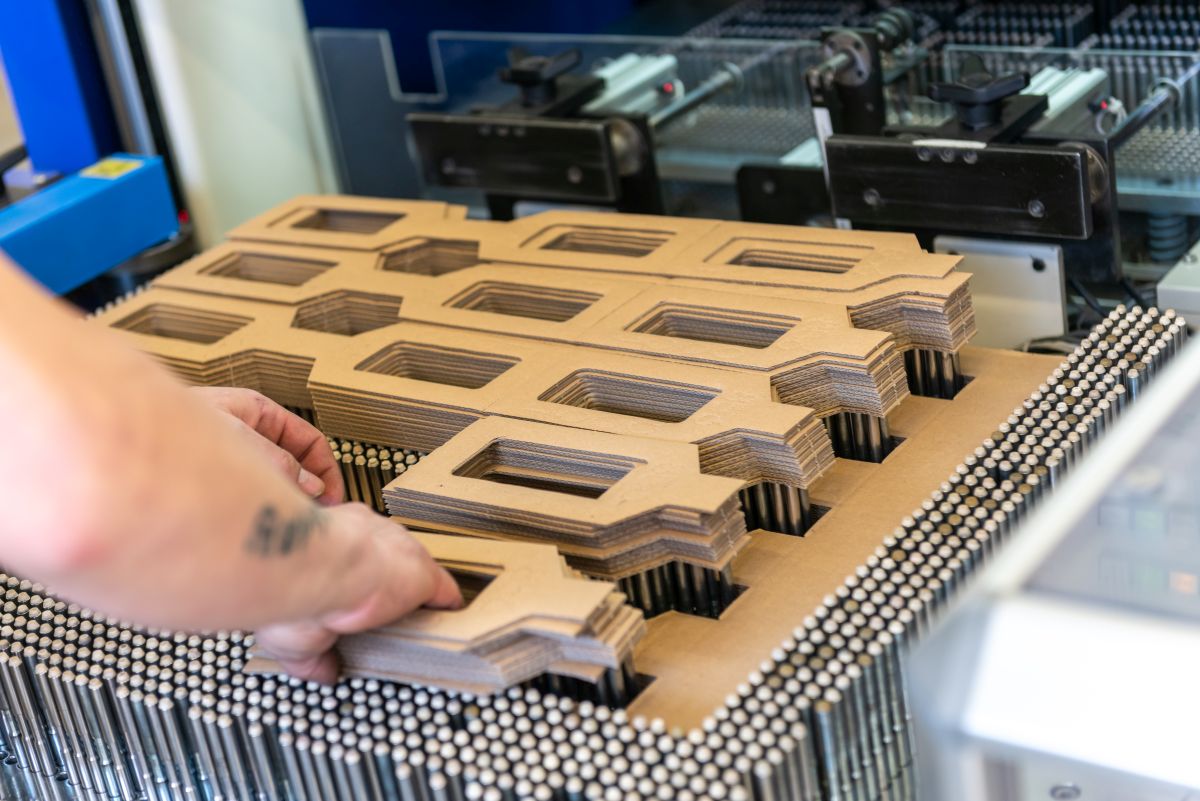

We commissioned a flatbed, automated diecutting machine.

We exhibited at the Pack & Gift fair of luxury packaging solutions in Paris.

We glue paper carrier bags by machine, which is done by few.

The crisis of the past two years showed that nothing will be the same way as before. Our most important aim is consolidation.

We preserve each other and our values.

We managed to strengthen our sales in the field of exports.

We purchased an land area of 8,000 square metres with a 2,500-sq.m hall.

We started the modernisation of our new business premises, as well as the construction of a new, 1,000-sq.m hall. We added a gilding machine and an automated diecutting tool making machine.

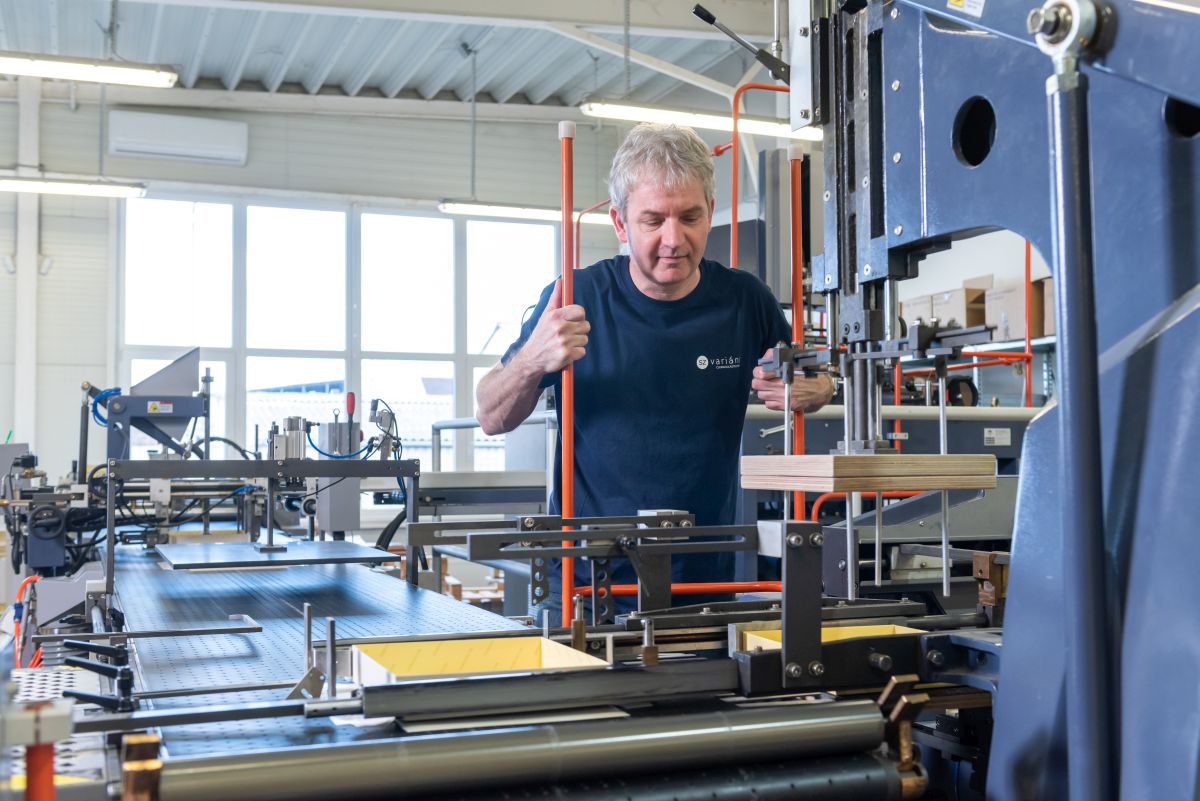

In the middle of the year, we moved to our new business premises. In creating our plant, we chose state-of-the-art energy solutions. One proof of this was the installation of a 50 kW solar system.

We commissioned a Rigid Box making machine, with a related casemaker line. Please watch our video of the machine »

We participated for the first time, as exhibitors, at the ISM ProSweets trade fair of packaging suppliers in the sweets industry, held in Cologne.

We made an increasing number of mounted boxes, using the Rigid Box line commissioned in the previous year.

Although we did not plan further investments in machinery, after a quick but successful decision, we bought a KAMA-type automatic diecutting machine, as well as a Japanese automatic separating machine, which is unique in Hungary. Never a better decision! Never a better year!

We commissioned a Heidelberg printing machine, as well as Gluejet-type automatic gluing table. With the help of the gluing table, we are able to increase our capacities for the making of high added value boxes. In addition to the purchasing of machinery, we also added a nearly 500 sq.m. of floor space.

Even with a series of Covid diseases throughout the year, we were able to cope with the increased production demands.

We have had to balance the unprecedented shortage of raw materials and the drastic increase in the prices of the base- and auxiliary materials.

By the end of the year, we have stated that we no longer see the problems that lie ahead as “difficulties”, we only consider them as tasks to be solved.

We learned something again!

We believe that the strength of a company is determined by its ability to weather an unexpected economic event, an economic crisis, financially and organisationally.

We believe that when we find ourselves in a difficult economic situation, as we did in 2023, we can only react to what happens. In similar events, we are not able to influence the financial circumstances.

More precisely, the strength of an economic entity is always measured by its exposure to the unexpected event. If it had a strong base in the first place, it is less likely to experience difficulties; if it had a high economic exposure, it could easily find itself in a financial crisis. With this in mind, we are pleased that we have managed the biggest inflation challenge and economic downturn in decades. While we did not fully meet our targets, we have nevertheless achieved a satisfactory level of performance for a challenging 2023.

We were not scared by special challenges, even if they appeared impossible at first sight

It is important for us to proceed not only according to our own course, but also to see new dimensions, forward-looking solutions. For this reason, we make an effort to be present at the specialised trade exhibitions and fairs every year. We have been to many professional events from Düsseldorf to Paris, on many occasions also as exhibitors.

Zsuzsa Rácsai, János Szakál, Irma Szakál

We were not scared by special challenges, even if they appeared impossible at first sight. We believe in continuous learning; we look at every packaging as a new challenge. Unusual designs also entail the use of unusual materials, as well as the combination of different materials. In a large part, this is what we owe our professional expertise to. This attitude continues to be rewarding today, as much as it was in 1996. For example, in Hungary, we were the first to use and are still unique in applying open microcorrugated paper in paper bags and wine boxes. This technology earned as the honour of becoming a supplier for IKEA. This was when we really understood how much opportunity is inherent in packaging, and what an important role it plays in the success of the product, or even the entire brand. After all, the fate of a product is decided on the shelves.

We switched to a way of thinking based on continuous development

We would like to be present as a true 21st-century company, with state-of-the-art machines, modern employees and strong philosophy. We established our work processes by learning from our mistakes and building on our experiences, also calling to help the Lean approach and the Kaizen principles. We learnt that even a small mistake can cause much damage. We believe that we can only be efficient if we are able to prepare, supervise, control and implement our work at a high quality, in a professional manner.

Customers should be able to remember our packaging solutions even after years

Our efforts are always aimed at ensuring that the packaging made by us should present the product and communicate its message, by informing customers on what they can expect from the product. By correctly choosing the function, the raw material and the extraordinary design, we strive to achieve that customers remember our packaging solutions even after years.